What Is the Maintenance Procedure of a Motor?

Electric motors are vital components in a wide range of applications, from manufacturing equipment to HVAC systems and electric vehicles. To ensure these motors operate efficiently and last as long as possible, regular electric motor maintenance is essential. Proper maintenance not only enhances motor performance but also helps prevent unexpected failures that can lead to costly downtime and repairs.

In this blog, we’ll outline the key maintenance procedures for electric motors, discuss why they’re important, and provide tips on how to keep your motors in top shape for optimal performance.

Table of Contents

Toggle1. Importance of Electric Motor Maintenance

Regular electric motor maintenance is crucial for ensuring the longevity and efficiency of the motor. Motors that are well-maintained typically experience fewer breakdowns and offer better performance over time. Maintenance also helps reduce energy consumption, prevent overheating, and avoid costly repairs.

Key Benefits of Regular Motor Maintenance:

- Increased Lifespan: Routine inspections and maintenance keep the motor’s components in good condition, which extends the motor’s service life.

- Improved Efficiency: Well-maintained motors run more efficiently, consuming less power and delivering better overall performance.

- Reduced Downtime: Early detection of potential issues through regular maintenance prevents unexpected breakdowns, reducing costly downtime.

- Cost Savings: Preventative maintenance can save money by addressing small issues before they become major problems, avoiding expensive repairs or replacements.

Now that we understand the importance of motor maintenance, let’s dive into the specific procedures involved in keeping an electric motor functioning at its best.

2. Motor Inspection and Cleaning

The first step in any electric motor maintenance procedure is a thorough inspection. Regular inspections allow you to spot potential issues before they become serious problems. During the inspection, it’s essential to check the motor’s exterior, wiring, and key components for any signs of wear, dirt buildup, or damage.

Steps for Inspecting and Cleaning an Electric Motor:

- Visual Inspection: Begin by visually inspecting the motor’s exterior. Look for any signs of damage, such as cracks, dents, or rust on the motor housing. Also, check for loose or disconnected wiring and ensure all electrical connections are secure.

- Check for Debris: Accumulation of dust, dirt, and other debris can obstruct airflow, leading to overheating. Clean the motor’s vents, fan blades, and cooling fins using compressed air or a soft brush to prevent debris buildup. If your motor is located in a dusty environment, more frequent cleaning may be required.

- Inspect for Corrosion or Moisture: Corrosion or moisture inside the motor can cause serious damage. Check for any signs of rust or water around the motor and ensure it’s operating in a dry, well-ventilated environment.

- Motor Enclosure: Ensure the motor’s enclosure or housing is in good condition and properly sealed to protect it from contaminants like dust, water, or chemicals.

Regular cleaning and inspection of your motor can help keep it running efficiently and prevent costly damage caused by debris or environmental factors.

3. Lubrication of Bearings

The bearings inside an electric motor play a critical role in reducing friction between moving parts, allowing the motor to run smoothly. Over time, bearings can become worn or dry, leading to increased friction and wear. Proper lubrication is a key part of electric motor maintenance, as it helps extend the life of the bearings and ensures the motor operates efficiently.

Steps for Bearing Lubrication:

- Check the Manufacturer’s Guidelines: Before lubricating the bearings, check the motor manufacturer’s recommendations for the type and amount of lubricant to use. Over-lubrication can be just as harmful as under-lubrication.

- Lubrication Frequency: Depending on the motor’s operating environment and duty cycle, bearings should be lubricated at regular intervals. Motors that operate continuously or in high-temperature environments may require more frequent lubrication.

- Apply the Lubricant: Use the appropriate lubricant and apply it to the bearings carefully, ensuring that you don’t overfill the bearing housing. Clean any excess grease or oil from the motor to avoid attracting dirt or debris.

By keeping bearings properly lubricated, you can reduce friction, prevent overheating, and extend the lifespan of both the bearings and the motor itself.

4. Checking Electrical Connections

Faulty or loose electrical connections can cause serious issues in an electric motor, including power loss, overheating, and motor failure. As part of regular electric motor maintenance, it’s important to inspect and tighten all electrical connections to ensure proper operation.

Steps for Checking Electrical Connections:

- Turn Off Power: Before inspecting or working on any electrical connections, make sure the power supply to the motor is switched off to avoid electrical shock or injury.

- Check for Loose Connections: Inspect the motor’s wiring and terminals for any loose or corroded connections. Loose connections can cause voltage drops and increased resistance, which can lead to overheating.

- Test Electrical Insulation: Use an insulation resistance tester (megohmmeter) to check the condition of the motor’s insulation. Weak or deteriorated insulation can result in short circuits or electrical leakage.

- Monitor Voltage and Current: Measure the voltage and current levels to ensure the motor is operating within its specified parameters. Any significant deviations from the normal range could indicate an issue with the electrical system or the motor itself.

Tightening connections and ensuring proper insulation helps maintain the motor’s electrical integrity and prevents potential malfunctions.

5. Monitoring Temperature and Vibration

Monitoring the operating temperature and vibration levels of an electric motor is critical for detecting potential problems early. Overheating and excessive vibration are both warning signs of motor malfunction and can lead to premature motor failure if not addressed.

Monitoring Temperature:

- Check for Overheating: Motors that overheat can suffer damage to internal components, including the windings and insulation. Use an infrared thermometer to regularly check the motor’s operating temperature. If the motor is running hotter than its specified range, investigate the cause immediately—this could be due to poor ventilation, overloading, or bearing issues.

- Ensure Proper Cooling: Ensure that the motor’s cooling system, such as fans or ventilation openings, is functioning correctly and free from obstructions.

Monitoring Vibration:

- Check for Unusual Vibration: Excessive vibration in an electric motor can indicate issues such as misaligned shafts, worn bearings, or imbalance. Vibration analyzers or sensors can be used to monitor vibration levels.

- Address Misalignment: Misalignment between the motor and the equipment it drives is a common cause of vibration. Regularly check for shaft misalignment and make any necessary adjustments to reduce stress on the motor.

By regularly monitoring temperature and vibration levels, you can identify issues before they cause severe damage, ensuring smoother operation and a longer lifespan for your motor.

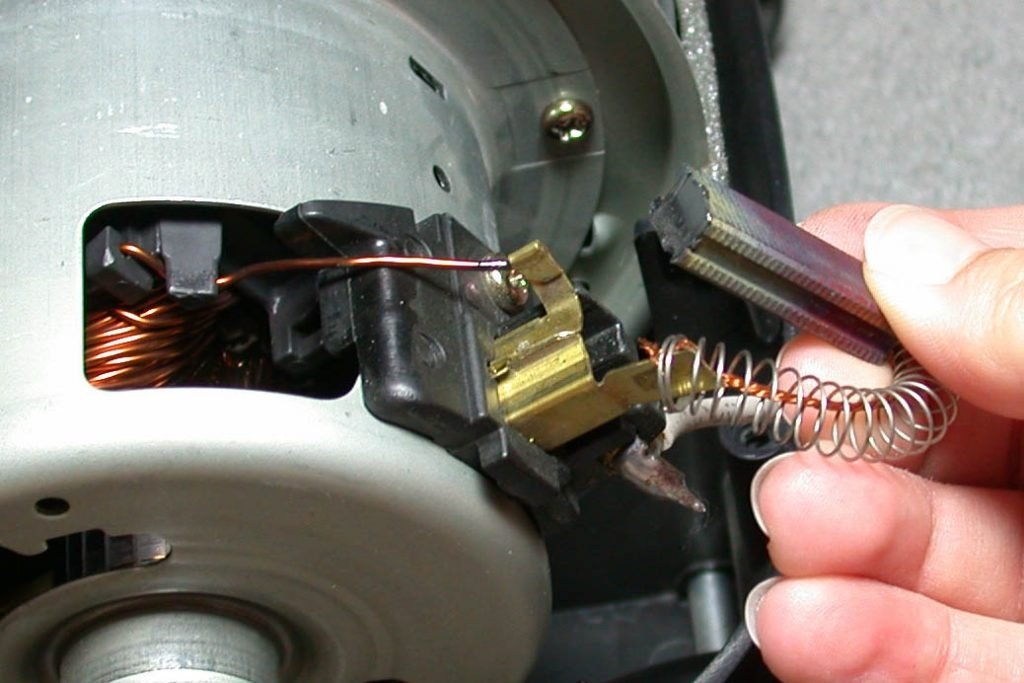

6. Testing Motor Windings

Motor windings are crucial for generating the electromagnetic field that powers the motor. Over time, windings can degrade due to heat, moisture, or electrical surges. Regular testing of motor windings is an essential part of electric motor maintenance to ensure they are functioning properly.

Steps for Testing Motor Windings:

- Insulation Resistance Test: Use a megohmmeter to test the insulation resistance of the motor windings. Low insulation resistance indicates that the windings may be deteriorating or damaged.

- Continuity Test: A continuity test ensures that the motor windings are not open or shorted. If the test shows a break in continuity, the motor windings may need repair or replacement.

- Visual Inspection: Visually inspect the motor windings for signs of discoloration or damage, which could indicate overheating or electrical faults.

Regular testing of the windings helps prevent electrical failures and ensures the motor can operate reliably under various conditions.

Conclusion

Electric motors are valuable assets that require regular care and attention to ensure optimal performance and longevity. Following a comprehensive electric motor maintenance routine that includes inspections, cleaning, lubrication, and electrical testing can significantly reduce the risk of breakdowns and costly repairs.

By scheduling regular maintenance and monitoring key factors such as temperature, vibration, and electrical connections, you can keep your electric motors running smoothly for years to come. For any serious issues or repairs, be sure to consult with professional technicians who specialize in electric motor maintenance to ensure your motors receive the best care possible.

Syed Azeem Haider is an enthusiastic writer, loves to write on social issues, current affairs, books and T.V reviews, currently working for homepick as a digital marketer.