The Corrugated Truth: Replacing Your Garage Roof Made Easy

Table of Contents

ToggleYour Guide to a New Garage Roof

Your garage is more than just a storage space; it’s a valuable asset protecting your belongings. But a failing corrugated roof can quickly compromise its function and value. If you’re facing leaks, damage, or simply considering an upgrade, knowing your options for corrugated garage roof replacement is essential.

We understand this can seem like a big project. That’s why we’ve put together this comprehensive guide. We’ll walk you through everything you need to know: from selecting the best materials and understanding costs, to the step-by-step replacement process. Our goal is to make your project straightforward and successful. For specific services and further details, you can also explore resources like the EMC corrugated garage roof replacement guide.

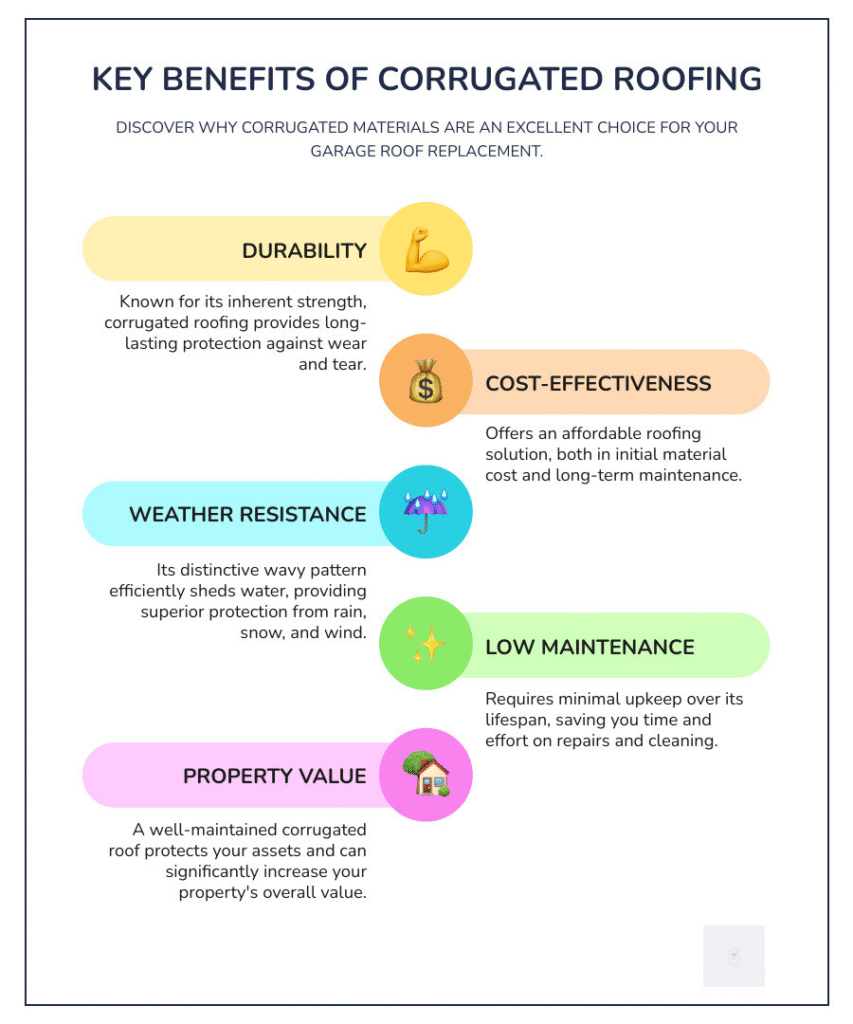

A well-maintained garage roof is crucial for protecting your vehicles, tools, and stored items from the elements. Beyond its practical utility, a garage also adds significant value to your property. Studies by the AA have shown that adding a garage space can increase a property’s value by up to 5%. Investing in a quality roof replacement, especially one made with durable corrugated materials, ensures that this asset remains protected and continues to contribute to your home’s overall value.

Corrugated roofing, characterized by its distinctive wavy pattern, is a popular choice for garages due to its inherent strength and efficient water-shedding capabilities. This design isn’t just for aesthetics; it significantly improves the material’s structural integrity without adding excessive weight. This makes it a robust yet practical solution for many outbuildings.

Is It Time for a Replacement? Key Warning Signs

Recognizing the signs that your corrugated garage roof needs attention is the first step towards preventing more extensive damage and costly repairs. While corrugated roofs are known for their longevity, even the most durable materials eventually succumb to wear and tear. Corrugated metal roofs, for instance, can last anywhere from 40 to 70 years with proper maintenance, but other materials might have shorter lifespans.

Here are the key indicators that it’s time to consider a replacement:

- Visible Deterioration: Look for general signs of aging such as warping, sagging, or brittleness in the panels. This is often the first visible cue that the material is losing its structural integrity.

- Cracks and Holes: Any visible cracks, punctures, or holes, no matter how small, are direct pathways for water intrusion. Impacts, extreme weather, or material degradation can cause these.

- Worn-Out Paint or Coating: For painted or coated corrugated sheets, peeling, chipping, or fading paint indicates that the protective layer is compromised. This exposes the underlying material to the elements, accelerating deterioration.

- Corrosion and Rust: For metal corrugated roofs, particularly, rust is a major concern. Once the protective coating (like galvanization) wears off, the metal is exposed to moisture and oxygen, leading to corrosion. This weakens the panels and can eventually lead to holes.

- Persistent Leaks: The most obvious sign of a failing roof is the presence of water inside your garage. Even small, intermittent leaks can lead to significant issues, such as mold growth, damage to stored items, and deterioration of the garage’s structure. If you’re constantly patching leaks, a full replacement is likely more cost-effective in the long run.

- Storm Damage: High winds, hail, or falling debris can cause immediate and severe damage to corrugated roofs, including dislodged panels, bent sections, or punctures. After a significant storm, always inspect your roof thoroughly.

- Lifespan Expectation: Consider the age of your current roof. Suppose it’s approaching or has exceeded its expected lifespan (e.g., 25-60 years for general corrugated roofing, 40-70 years for metal). In that case, it’s prudent to plan for replacement even if major issues aren’t yet apparent.

For a deeper dive into assessing when your corrugated roofing needs replacement, you may find additional insights helpful in this resource: When Do I Need to Replace My Corrugated Roofing?

Navigating Your Options: A Guide to Corrugated Roofing Materials

When considering a corrugated garage roof replacement, understanding the different material options available is crucial. Each comes with its own set of advantages and disadvantages regarding durability, cost, and maintenance. The corrugated profile itself offers inherent benefits across all material types, such as increased strength-to-weight ratio and efficient water runoff, making them excellent choices for garage roofs.

Here’s a breakdown of common corrugated roofing materials:

Material Type Lifespan (Approx.) Cost (Relative) Durability Maintenance (Relative)

Metal (Steel, Aluminum) 40-70 years Medium-High Excellent (weather, fire, impact) Low

Bitumen 20+ years Low-Medium Good (weather, UV, noise reduction) Low

Plastic (PVC, Polycarbonate) 15-20 years Low Moderate (lightweight, UV filter, brittle) Low Fibreglass 15-20 years Medium Moderate (insulation, light transmission) Low

Fibre Cement 60+ years Medium Excellent (fire, moisture, salt air, quiet) Very Low Metal Roofing (Steel, Aluminum)

Metal corrugated sheets, typically made from galvanized steel or aluminum, are a top contender for garage roofs. Their robust nature provides exceptional durability, often lasting 40 to 70 years. They are highly resistant to fire, rot, and pests, and can withstand extreme weather conditions. The corrugations add significant strength, allowing for lighter gauge materials to be used without sacrificing performance. Many metal roofs are also made from recycled materials and are fully recyclable at the end of their long life, making them an eco-friendly option. However, they can be noisy during heavy rain or hail, and softer metals are susceptible to denting. For more on the robust nature of these roofs, explore the benefits of corrugated metal roofs.

Bitumen Roofing

Bitumen corrugated sheets are a lightweight, affordable, and easy-to-install option. They are often made from recycled cellulose fibers saturated with bitumen, making them a more sustainable choice. These sheets are renowned for their noise-reducing properties, UV resistance, and ability to withstand harsh weather conditions. While their lifespan (around 20 years or more) may be shorter than that of metal, their cost-effectiveness and ease of handling make them a popular, DIY-friendly solution. They are virtually maintenance-free and can be installed on low-pitch roofs. If you’re considering this option, you might find a guide on how to replace your garage roof with bitumen roof sheets particularly useful.

Plastic & Fibreglass Roofing

Plastic (PVC or polycarbonate) and fiberglass corrugated sheets offer distinct advantages, primarily their lightweight nature and ease of installation, often making them a cost-effective choice for DIY projects. Many plastic options are translucent, allowing natural light into the garage while filtering out harmful UV rays. Fibreglass can also offer better insulation properties than metal or plastic. However, plastic sheets can be more brittle than metal or fibre cement and may not provide the same level of impact resistance. Their lifespan is generally shorter, typically 15 to 20 years.

Environmental Considerations

The environmental impact of your chosen roofing material is a growing concern. Metal corrugated roofs, especially those made from steel, are often manufactured from recycled content and are 100% recyclable at the end of their lifespan, thereby reducing landfill waste. Bitumen sheets, as mentioned, can contain a significant percentage of recycled materials. Plastic and fiberglass options can also incorporate recycled content, although their end-of-life recycling can be more complex, depending on local facilities. Opting for materials with a long lifespan inherently reduces waste and the need for frequent replacements.

The Financials: Understanding the Cost of an EMC Corrugated Garage Roof Replacement

Understanding the costs associated with a corrugated garage roof replacement is essential for effective budgeting. The total expense can vary significantly based on several factors; however, corrugated roofing is generally considered a cost-effective option. In the UK, the average cost of fitting a metal roofing sheet for garages can range from approximately £750 to £ 3,000. In the US, corrugated roofing can often be installed for around $3 to $4 per square foot.

Key Factors in Your EMC Corrugated Garage Roof Replacement Cost

- Material Choice: As discussed, different materials (metal, bitumen, plastic, fibre cement) come at varying price points. Higher-quality metals with specialized coatings or thicker gauges will naturally cost more.

- Garage Size and Roof Complexity:Larger garages require more materials and labor. Complex roof designs with multiple angles, valleys, or penetrations (such as skylights or vents) will increase installation time and material waste, thereby raising costs.

- Labor Costs: This is a significant component. Professional installation ensures proper technique, safety, and adherence to building codes. Labor rates vary by region and the complexity of the job.

- Old Roof Disposal: Removing the old roof material incurs costs for labor and disposal fees. This can be particularly expensive if the old roof contains hazardous materials, such as asbestos.

- Asbestos Removal: If your existing garage roof contains asbestos-cement sheets, professional removal is legally required and incurs substantial costs due to specialized handling and disposal protocols. Never attempt to remove asbestos yourself.

- Structural Repairs: If the underlying roof structure (purlins, rafters, decking) is damaged by rot, pests, or age, these repairs must be completed before new roofing can be installed, adding to the overall cost.

- Flashing and Trim: Essential components, such as ridge caps, barge boards, and wall flashings, are necessary for a watertight and finished roof. The type and material of these elements will affect the price.

- Geographic Location: Costs for materials and labor can fluctuate based on your location. For instance, prices in London might differ significantly from those in rural areas. You can often find local pricing guides for corrugated roofing in your area.

- Project Timeline: Urgent or rushed projects might incur higher labor costs.

DIY vs. Professional Installation

While the idea of a DIY corrugated garage roof replacement might seem appealing for cost savings, it’s crucial to weigh the risks and benefits.

- Safety Risks: Working on a roof, especially with large, potentially sharp corrugated sheets, carries significant safety risks. Falls are an important concern, and improper handling can lead to cuts or other injuries.

- Tool Requirements: Specialized tools may be required for cutting, fastening, and lifting, which can incur unexpected expenses.

- Warranty Voiding: Many roofing material manufacturers’ warranties are contingent on professional installation. Improper DIY installation could void your warranty, leaving you unprotected in the event of issues.

- Long-Term Performance: Professional roofers have the experience and expertise to ensure proper installation techniques, correct overlaps, secure fastening, and watertight seals. Mistakes in a DIY job can lead to leaks, premature failure, and more expensive repairs down the line.

- Professional Expertise: A professional will accurately assess the underlying structure, address any unexpected issues, and ensure the roof complies with local building codes.

For a project as important as your garage roof, entrusting it to experienced professionals can save you time, stress, and money in the long run. When you’re ready to explore options for a new roof, consider consulting with experts who specialize in EMC corrugated garage roof replacement to ensure a quality outcome.

The Replacement Process: From Old to New

Replacing your garage roof, especially with corrugated sheets, involves several key stages, from preparing the site to the final touches. A systematic approach ensures safety, efficiency, and a long-lasting, watertight result.

Safety First: The Asbestos Warning

A critical initial step, particularly for older garages, is to determine if your existing roof contains asbestos-cement sheets. Asbestos was a common building material for many decades due to its durability and fire resistance. However, if disturbed, asbestos fibers can be released into the air, posing severe health hazards.

- Identification: Asbestos-cement sheets often have a distinct, grey, corrugated appearance. If your garage was built before 2000, there’s a strong possibility that it contains asbestos.

- Professional Testing: Never assume or attempt to test for asbestos yourself. It’s imperative to hire a qualified and licensed asbestos surveyor to take samples and confirm its presence.

- Safe Removal Protocols: If asbestos is confirmed, professional removal by a licensed contractor is legally required and essential for safety. They possess the specialized equipment, training, and disposal methods necessary to manage asbestos safely and in accordance with legal requirements. DIY removal is highly dangerous and illegal in many jurisdictions. Discussions around repairing garage roofs with asbestos sheets often highlight the complexities and dangers involved, underscoring the need for professional handling.

The Step-by-Step Installation Guide

Once the old roof is safely removed and any asbestos dealt with, the installation of your new corrugated garage roof can begin.

- Old Roof Removal: Carefully dismantle and remove the existing roofing material. Ensure the area is clear of debris.

- Structural Inspection: With the old roof off, thoroughly inspect the underlying structure, including rafters, purlins, and any decking. Check for rot, insect damage, or structural weaknesses. Repair or replace any compromised components.

- Purlin and Batten Repair/Installation:Ensure purlins (horizontal supports) are securely fastened and spaced correctly to support the new corrugated sheets. If installing new battens, ensure they are level and properly aligned.

- New Sheet Layout: Plan the layout of your new corrugated sheets to minimize cuts and ensure proper overlap for optimal performance. Typically, sheets are laid starting from the eaves, working upwards towards the ridge, and overlapping horizontally against the prevailing wind direction.

- Overlapping Technique: Corrugated sheets require specific overlapping to ensure a watertight seal. Generally, a two-rib overlap is recommended, and manufacturers often specify a minimum end-lap (where one sheet overlaps another along its length) of around 6 inches. Using butyl tape or sealant within these overlaps is frequently recommended for enhanced waterproofing.

- Fastening on Peaks: Corrugated sheets should be secured through the peaks (the raised sections of the corrugation), not the troughs. This prevents water from pooling around the fasteners, reducing the risk of leaks. Use self-tapping screws with neoprene washers to create a tight, waterproof seal. Ensure fasteners are driven straight and not overtightened.

- Ridge Cap Installation: Once all sheets are in place, install the ridge cap along the apex of the roof. This seals the joint between the two sides of the roof, providing a finished appearance. Secure it firmly with appropriate fasteners.

- Edge Trims and Flashings: Install all necessary edge trims (barge boards) and flashings around walls, chimneys, or other penetrations to ensure a completely watertight and wind-resistant roof.

Post-Installation: Maintenance for a Long-Lasting Roof

Proper maintenance is key to maximizing the lifespan of your new corrugated garage roof.

- Regular Cleaning: Keep the roof free of debris such as leaves, branches, and dirt. Accumulations can trap moisture, promote corrosion, and block water flow.

- Debris Removal: Regularly clear gutters and downspouts to ensure efficient drainage. Blocked drains can cause water to back up onto the roof, leading to leaks and damage.

- Fastener Inspection: Periodically check all fasteners (screws) for tightness. Over time, temperature fluctuations can cause them to loosen, or the washers can degrade. Tighten or replace as needed.

- Sealant Checks: Inspect any sealed areas, such as overlaps or flashings, for cracks or deterioration in the sealant. Reapply sealant as necessary to maintain a watertight barrier.

- Minor Issue Prevention: Address small issues, such as minor dents or scratches, promptly to prevent them from escalating into larger problems. For example, a minor leak can be temporarily patched, but consistent monitoring is key to preventing further damage, as discussed in various forums on corrugated roof leaks.

Frequently Asked Questions about Corrugated Garage Roofs

We often encounter common questions from homeowners considering a replacement for their corrugated garage roof. Here are some of the most frequently asked questions and our corresponding insights.

What are the main advantages of a corrugated roof for a garage?

Corrugated roofing offers several compelling advantages for garages:

- Strength-to-Weight Ratio: The unique wavy profile significantly enhances the material’s structural rigidity, enabling lighter sheets that remain incredibly strong.

- Superior Water Shedding: The ridges and grooves are designed to channel rainwater efficiently off the roof, preventing pooling and reducing the risk of leaks, especially when installed at a sufficient pitch.

- Durability: Depending on the material (especially metal and fibre cement), corrugated roofs are highly durable, resistant to impact, pests, and harsh weather conditions, offering a long lifespan.

- Cost-Effectiveness: Compared to many other roofing types, corrugated sheets are often more affordable to purchase and install, providing excellent value for money.

- Variety of Materials: With options such as metal, bitumen, plastic, and fibre cement, there’s a corrugated solution to suit various budgets, aesthetic preferences, and performance requirements.

Can I install a corrugated roof over my old garage roof?

While it might seem like a time-saving and cost-effective solution, installing a new corrugated roof directly over an old one is generally not recommended. Here’s why:

- Moisture Trapping Risk: Trapping old, potentially damp roofing materials beneath new ones can lead to moisture buildup, promoting rot, mold, and mildew in the underlying structure.

- Hidden Structural Damage: Covering the old roof prevents a thorough inspection of the underlying rafters and purlins. You might be covering up existing damage that could compromise the integrity of your new roof.

- Weight Load: Adding a new layer of roofing increases the overall weight on the garage structure, which may not be designed to support the additional load.

- Best Practice is Full Removal: For these reasons, the best practice is always to fully remove the old roof, inspect and repair the substructure, and then install the new corrugated sheets. This ensures a clean, solid base, maximizing the lifespan and performance of your replacement roof.

How do I handle a leak in my corrugated roof?

Dealing with a leak promptly is crucial to prevent further damage.

- Source Identification: The first step is to locate the source of the leak accurately. Water can travel, so the wet spot inside might not be directly below the entry point. Look for signs on the roof, such as loose fasteners, damaged washers, cracks, punctures, or compromised overlaps.

- Loose Fasteners: Often, leaks occur around screws that have loosened or whose rubber washers have degraded. Tightening the screw or replacing it with a new one (ensuring a fresh neoprene washer) can often resolve this.

- Failed Sealant: Check any areas where sealant was applied, such as overlaps or around flashings. If the sealant is cracked, dried out, or peeling, clean the area and reapply a high-quality, exterior-grade roofing sealant.

- Cracks or Punctures: For small cracks or holes, a temporary patch can be applied using specialized roofing repair tape or a fiber-reinforced sealant. For larger damage, a section of the sheet may need to be replaced.

- Temporary Patch vs. Professional Repair: While temporary fixes can buy you time, persistent or multiple leaks or significant damage indicate a need for a professional assessment. A professional can identify underlying issues and provide a lasting solution.

- Emergency Response: In an emergency, a tarp can be secured over the leaking area to provide temporary protection until repairs can be made.

Conclusion

Replacing your corrugated garage roof is a significant home improvement that protects your assets and improves your property’s value. By understanding the different material options, recognizing the signs of wear, and being aware of the installation process and associated costs, you can make informed decisions.

The durability and cost-effectiveness of corrugated roofing make it an excellent choice for many garages. However, the importance of material choice, proper installation techniques, and ongoing maintenance cannot be overstated. When in doubt, consulting with experienced roofing professionals ensures your garage roof replacement is handled safely, efficiently, and to the highest standards, providing you with peace of mind for years to come.