Equipping for Success: Choosing the Right Commercial Kitchen Charbroilers

Table of Contents

ToggleUnderstanding Charbroiler Fundamentals

Running a successful restaurant demands more than just great recipes. It requires a well-oiled machine where every piece of equipment plays its part. From initial ingredient storage to the final plated dish, a smooth kitchen flow is critical.

The charbroiler often stands as the heart of a commercial kitchen. It’s where signature smoky flavors and perfect sear marks are born. This essential tool helps define your menu and keeps customers coming back.

Choosing the right equipment, especially your charbroiler, impacts everything. It affects efficiency, food quality, and your entire kitchen’s operation. Making informed decisions is key to a thriving culinary business.

We will guide you through selecting the ideal commercial charbroiler. We will cover vital aspects like fuel sources, sizing, and durable construction. Our aim is to help you equip your kitchen for lasting success.

When we talk about charbroilers in a commercial setting, we’re discussing equipment built for endurance and consistent performance under intense pressure. Unlike residential grills designed for occasional backyard use, commercial charbroilers are engineered to handle high-volume cooking, often for hours on end, day after day. This distinction is crucial for any food service establishment.

Commercial charbroilers boast superior durability, typically constructed from heavy-duty materials like stainless steel and cast iron, designed to withstand the rigorous demands of a busy kitchen. They also feature advanced heat recovery systems, ensuring that cooking temperatures remain stable even when large quantities of cold food are placed on the grates. This rapid heat recovery is paramount for maintaining efficiency and food quality during peak service hours. Furthermore, commercial units are often NSF certified, meaning they meet strict public health and safety standards, a non-negotiable requirement for professional kitchens.

Why a Commercial Charbroiler is an Essential Investment

Investing in a high-quality commercial charbroiler isn’t just about cooking food; it’s about elevating your entire culinary operation. Here’s why it’s an essential investment:

- Consistent Temperature: Commercial charbroilers are designed for precise temperature control across the entire cooking surface. This consistency ensures that every steak, burger, or vegetable is cooked evenly, reducing waste and guaranteeing a high-quality product for your customers. In a environment, this reliability is invaluable.

- Faster Cooking Times: With powerful burners and efficient heat distribution, commercial charbroilers can reach and maintain optimal cooking temperatures quickly. This translates to faster cooking times, allowing your kitchen to handle more orders and turn tables more efficiently, directly impacting your bottom line.

- Flavor Improvement: The intense, direct heat of a charbroiler creates the distinctive smoky flavor and beautiful sear marks that diners crave. This signature charbroiled taste can differentiate your menu and become a key selling point for your establishment. The caramelization achieved on a charbroiler adds depth and complexity to a wide range of dishes.

- Menu Versatility: A charbroiler opens up a world of culinary possibilities. From grilling meats and seafood to charring vegetables and even certain fruits, its versatility allows you to expand your menu offerings and cater to diverse tastes. It’s not just for burgers and steaks; think grilled halloumi, charred corn, or even grilled pineapple for desserts.

- Customer Appeal: There’s an undeniable appeal to charbroiled items. The visual aesthetics of grill marks and the aromatic smoky scent contribute significantly to the dining experience. Customers often associate charbroiled dishes with freshness, quality, and a premium dining experience, which can improve your restaurant’s reputation and attract repeat business.

Key Considerations for Your Commercial Kitchen Equipment

Selecting the right charbroiler involves a careful evaluation of several critical factors. These considerations will ensure that the equipment you choose not only meets your operational needs but also contributes to the efficiency and success of your kitchen. We need to think about BTU ratings, which indicate the power and heat output; the cooking surface area, which dictates capacity; the heat source, which impacts flavor and cost; material quality, for durability; and the overall footprint, to fit your kitchen layout.

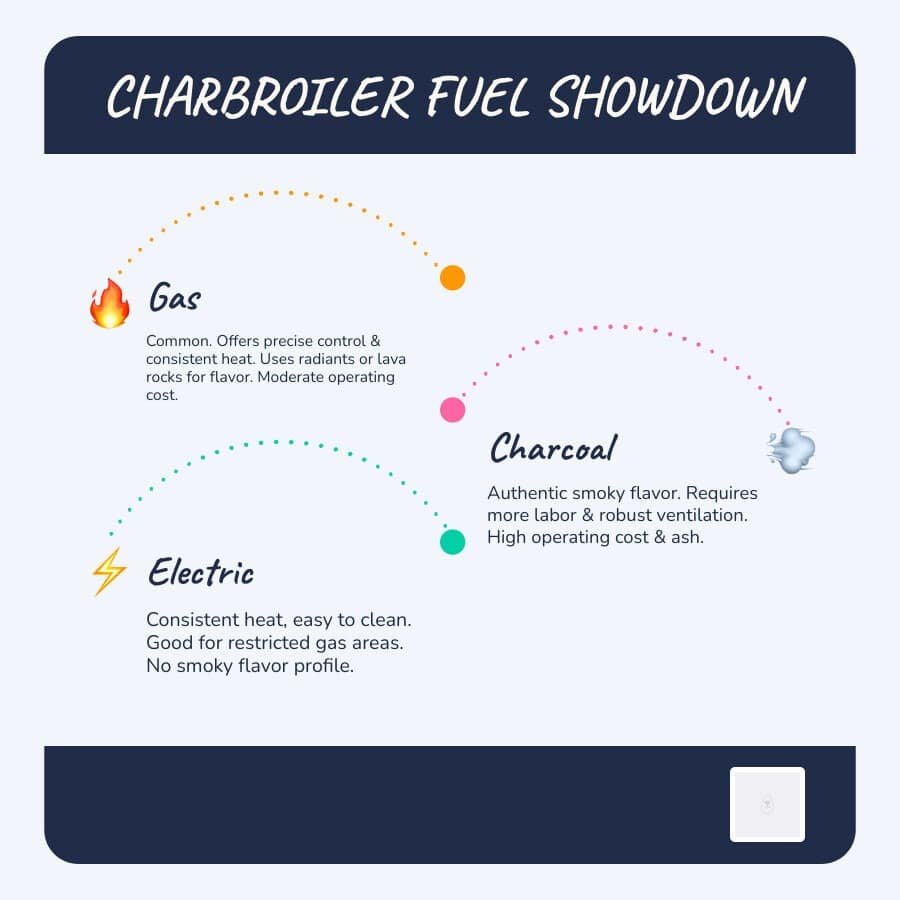

Fuel Source Showdown: Gas vs. Charcoal vs. Electric

The choice of fuel source is one of the most fundamental decisions when selecting a commercial charbroiler, as it significantly impacts flavor profile, operating costs, and kitchen logistics.

- Gas Charbroilers (Natural Gas or Propane): These are the most common in commercial kitchens due to their convenience and control. Gas charbroilers typically use either radiant heat or lava rocks to distribute heat.

- Radiant Heat: These units feature metal radiants (often ceramic or stainless steel) positioned above the burners. The flames heat these radiants, which then emit infrared heat to the cooking surface. This provides even heat distribution and is relatively easy to clean.

- Lava Rocks/Ceramic Briquettes: In these models, lava rocks or ceramic briquettes are placed above the burners. When heated, they radiate heat to the grates and absorb drippings, creating smoke that imparts a distinct charbroiled flavor. They offer a more traditional charbroiled taste but require more frequent cleaning and replacement of the media.

- Infrared Burners: Some high-end gas charbroilers use infrared burners, which produce extremely high, even heat quickly. They are excellent for searing and offer precise temperature control.

- Charcoal Charbroilers: For the most authentic smoky flavor, charcoal charbroilers are unparalleled. They use lump charcoal or briquettes, providing intense heat and a rich, smoky aroma that gas or electric units struggle to replicate. However, they require more labor to manage the charcoal, produce more ash, and demand robust ventilation. Temperature control can also be more challenging.

- Electric Charbroilers: These units are a good option where gas lines are unavailable or restricted. They offer consistent heat and are generally easier to clean than gas models. While they don’t produce the same smoky flavor as charcoal or lava rock gas units, they are efficient and provide precise temperature control. They often rely on heating elements directly beneath the grates.

Here’s a comparative overview:

Feature Gas Charbroiler (Radiant/Lava Rock) Charcoal Charbroiler Electric Charbroiler Initial CostModerate Low to Moderate Moderate to High Operating Cost Moderate (Gas) High (Charcoal, Labor) Moderate (Electricity) Flavor ProfileGood, smoky (especially lava rock) Excellent, authentic smoky Good, no smoke flavor Cleanup Moderate (radiants easier) High (ash, grease) Easy Temp. ConsistencyVery Good Challenging Excellent Heat Up Time Fast Slow Moderate Ventilation Needs High Very High High Sizing and Capacity: Matching the Broiler to Your Menu

Choosing the correct size and capacity for your charbroiler is crucial for operational efficiency and customer satisfaction. An undersized unit will lead to bottlenecks during peak hours, while an oversized one wastes space and energy.

- Peak Hour Demand: Analyze your restaurant’s busiest periods. How many charbroiled items do you typically sell per hour? This will help determine the minimum cooking surface area you need. Consider how many items can be cooked simultaneously without compromising quality.

- Menu Complexity: A diverse menu with many charbroiled options might require a larger unit or one with multiple heat zones for different cooking temperatures. If your menu is simpler, focusing on a few signature charbroiled dishes, you might opt for a more specialized, smaller unit.

- Countertop Models: Ideal for smaller kitchens or those with limited floor space, countertop charbroilers offer flexibility. They can be placed on existing equipment stands or worktables.

- Freestanding Units: These are larger, more powerful units designed for high-volume operations. They typically come with integrated stands and often offer more features and cooking zones.

- Available Space: Measure your kitchen’s available footprint carefully. Don’t forget to account for necessary clearances around the unit for ventilation, cleaning, and safety.

- Future Growth: While it’s important to meet current needs, consider your restaurant’s potential for growth. Investing in a slightly larger unit now might save you from needing to upgrade sooner than anticipated.

Construction and Durability in Commercial Kitchen Equipment

The longevity and performance of your charbroiler are heavily dependent on its construction and the quality of its materials. Commercial kitchens are harsh environments, and equipment must be built to last.

- Stainless Steel Body: Look for charbroilers with heavy-gauge stainless steel construction for the exterior and often the interior components. Stainless steel is durable, corrosion-resistant, and easy to clean, meeting stringent hygiene standards.

- Cast Iron Grates: Cast iron grates are preferred for their excellent heat retention and ability to create perfect sear marks. They are heavy-duty and can withstand intense heat over long periods. Some models offer adjustable grates, allowing chefs to control the distance from the heat source for different cooking needs.

- Adjustable Grates: The ability to adjust grate height can be a significant advantage, providing greater control over cooking intensity and preventing burning for delicate items while ensuring a strong sear for others.

- Welded Seams: High-quality commercial charbroilers feature fully welded seams rather than bolted or riveted construction. Welded seams provide superior structural integrity, prevent grease and food particles from accumulating in crevices, and make cleaning much easier.

- Grease Management Systems: An efficient grease management system is vital for safety and hygiene. Look for models with large, easily removable grease pans or drip trays that collect rendered fat and food debris. Some advanced systems include internal baffling to direct grease away from burners, reducing flare-ups.

- Drip Trays: Easily accessible and cleanable drip trays are essential for daily maintenance, preventing grease buildup that can become a fire hazard.

Creating a Cohesive Kitchen Ecosystem

A commercial kitchen is a complex ecosystem, and the charbroiler, while central, is just one component. For optimal efficiency and food safety, every piece of equipment must integrate seamlessly into the overall kitchen workflow. This includes everything from ventilation hoods that manage smoke and heat, to prep stations where ingredients are readied, and crucially, cold storage solutions that keep everything fresh and safe.

The importance of reliable refrigeration can’t be overstated. From walk-ins to reach-in units like a Commercial kitchen 2 door freezer, proper cold storage is critical for food safety and inventory management. Imagine a busy service where your charbroiler is perfectly searing steaks, but your ingredients are not properly chilled or easily accessible. This creates bottlenecks and compromises food quality.

Integrating your charbroiler with adequate prep stations nearby ensures that ingredients are ready to hit the grates without unnecessary movement or delay. Effective ventilation hoods are non-negotiable, not only to remove smoke and grease but also to maintain a comfortable and safe working environment for your staff.

When we design a kitchen, we always consider the flow of ingredients from delivery to storage, prep, cooking, and finally, plating. This involves thinking about how various refrigeration units, such as a perfect freezer for your restaurant, fit into the layout. For high-volume establishments, understanding the nuances of different freezer types, including the benefits of multi-door models, is key. If you’re looking to maximize storage and efficiency, exploring topics like everything you need to know about commercial freezers can provide valuable insights into optimizing your cold storage strategy. A well-planned kitchen ensures that your charbroiler can operate at its peak, supported by an efficient system for ingredient handling and storage.

Installation, Maintenance, and Safety Protocols

The performance, longevity, and safety of your commercial charbroiler are heavily reliant on proper installation, diligent maintenance, and strict adherence to safety protocols. These are not areas where shortcuts should ever be taken.

Professional Installation: Commercial charbroilers require professional installation by certified technicians. This is especially true for gas units, where proper gas line connections are critical to prevent leaks and ensure efficient fuel delivery. Electrical requirements must also be met precisely, including dedicated circuits and appropriate voltage. Incorrect installation can lead to equipment malfunction, energy inefficiency, and, most critically, safety hazards like fires or gas leaks. Always consult local building codes and fire regulations, as these dictate specific requirements for ventilation, clearances, and fire suppression systems.

Local Ventilation Codes: A robust ventilation system, specifically a Type I hood, is mandatory above charbroilers. This system is designed to capture and remove grease-laden vapors, smoke, and heat. Local codes will specify minimum airflow rates, ductwork requirements, and the need for makeup air systems to ensure proper air balance in the kitchen. Neglecting ventilation can lead to an unhealthy working environment, grease buildup, and increased fire risk.

Maintenance for Longevity and Performance: Regular maintenance is key to keeping your charbroiler in top condition and extending its lifespan.

- Daily Cleaning Tasks:Scrape and clean grates after each use to remove food residue.

- Empty and clean grease trays/pans.

- Wipe down exterior surfaces.

- Weekly Cleaning Tasks:Deep clean grates, potentially soaking them in degreaser.

- Clean under the grates, including radiants or lava rocks. Replace lava rocks/ceramic briquettes as needed.

- Inspect burners for blockages or damage.

- Clean around and beneath the unit, ensuring no grease buildup on floors or walls.

- Check gas connections for any signs of wear or leaks (for gas units).

Seasoning Grates: For cast iron grates, proper seasoning is essential, especially when new. This creates a non-stick surface and protects the iron from rust. Regular re-seasoning, particularly after deep cleaning, helps maintain this protective layer.

Burner Maintenance: Periodically inspect burners for blockages from food debris or grease. Clean burner ports with a wire brush to ensure even flame distribution. Uneven flames can lead to inconsistent cooking and energy waste.

Fire Suppression Systems: All commercial charbroilers must be installed under an approved fire suppression system. These systems are designed to automatically detect and extinguish fires, providing a critical layer of safety in a high-risk environment. Regular inspection and maintenance of these systems by certified professionals are legally required and paramount for kitchen safety, adhering to standards set by organizations like the NFPA (National Fire Protection Association).

Frequently Asked Questions about Commercial Charbroilers

We often hear similar questions from restaurateurs looking to invest in a new charbroiler. Here are some of the most common inquiries and our expert insights to help you make an informed decision.

How do I choose the right size charbroiler for my restaurant?

Choosing the right size is paramount for efficiency and cost-effectiveness. We recommend a multi-faceted approach:

- Calculate Peak Demand: Start by analyzing your busiest service periods. How many charbroiled items do you realistically expect to sell per hour? This will give you a baseline for the required cooking surface area.

- Analyze Your Menu: A diverse menu with many charbroiled items might necessitate a larger unit or one with multiple cooking zones to handle different temperatures simultaneously. If your menu is highly focused, a smaller, specialized unit might suffice.

- Measure Available Space: Accurately measure the footprint available in your kitchen. Remember to account for necessary clearances around the unit for ventilation, cleaning, and safe operation. Consider both countertop and freestanding models based on your space constraints.

- Consider Future Growth: While it’s tempting to buy for current needs, think about your restaurant’s potential for expansion. Investing in a slightly larger unit now could save you the cost and disruption of an upgrade down the line.

What is the difference between radiant and lava rock gas charbroilers?

Both radiant and lava rock gas charbroilers use gas as a fuel source but differ significantly in how heat is transferred and the flavor profile they impart:

- Radiant Heat Charbroilers:Mechanism: These units use metal (often ceramic or stainless steel) “radiants” positioned above the gas burners. The flames heat these radiants, which then emit infrared heat directly to the cooking surface.

- Pros: Offer very even heat distribution across the grates. They are generally easier to clean as there are no porous rocks to absorb grease. Less prone to flare-ups since drippings hit the radiants and vaporize quickly.

- Cons: The “smoky” flavor might be less pronounced compared to lava rock models, as drippings vaporize rather than smolder.

- Lava Rock/Ceramic Briquette Charbroilers:Mechanism: In these models, lava rocks or ceramic briquettes are placed directly over the gas burners. When heated, these porous materials radiate heat to the cooking surface. Drippings from food fall onto the hot rocks, creating smoke and steam, which infuse the food with a distinctive charbroiled flavor.

- Pros: Delivers a more traditional, authentic smoky charbroiled flavor due to the interaction of drippings with the hot rocks.

- Cons: Requires more maintenance; lava rocks need to be cleaned or replaced periodically as they absorb grease and can become saturated, leading to excessive smoke and flare-ups. Temperature consistency can sometimes be slightly less even than radiant models.

- Flare-up Control: While they offer great flavor, lava rock units can be more prone to flare-ups if grease builds up on the rocks.

The choice depends on your desired flavor profile and willingness to manage the associated maintenance.

What are the ventilation requirements for a commercial charbroiler?

Ventilation is a critical safety and operational aspect for any commercial charbroiler. We cannot stress enough the importance of proper ventilation.

- Type I Hood: A commercial charbroiler absolutely requires a Type I (grease-rated) exhaust hood. This hood is specifically designed to capture and remove grease-laden vapors, smoke, and heat produced during charbroiling.

- Makeup Air Systems: For every cubic foot of air exhausted by the hood, an equal amount of “makeup air” must be introduced into the kitchen. This prevents negative air pressure, which can lead to inefficient hood performance, uncomfortable drafts, and even back-drafting of combustion byproducts.

- Local Fire Codes: Ventilation requirements are strictly governed by local fire codes and building regulations. These codes will specify minimum exhaust rates (CFM), ductwork materials and dimensions, fire suppression system integration, and necessary clearances from combustible materials.

- Professional Consultation: It is imperative to consult with a qualified HVAC engineer or kitchen design professional to ensure your ventilation system is correctly sized, designed, and installed according to all applicable local and national codes. This not only guarantees safety and compliance but also optimizes kitchen comfort and energy efficiency. Regular cleaning and maintenance of the hood and ductwork are also crucial to prevent grease buildup, which is a major fire hazard.

Conclusion

Equipping your kitchen for success begins with making informed decisions about your core equipment. The commercial charbroiler, as we’ve explored, is far more than just a cooking appliance; it’s a long-term investment that significantly impacts your menu’s quality, your kitchen’s efficiency, and ultimately, your restaurant’s profitability.

From understanding the fundamental differences between commercial and residential models to carefully considering fuel sources, sizing, and construction, every choice plays a vital role. We’ve seen how the right charbroiler can offer consistent temperatures, faster cooking times, and that irresistible smoky flavor that keeps customers coming back for more. Moreover, integrating your charbroiler into a cohesive kitchen ecosystem, supported by efficient cold storage and robust ventilation, is essential for seamless operation and food safety.

Diligent installation, maintenance, and adherence to safety protocols are not just best practices—they are non-negotiable requirements for a safe and successful kitchen. Take the time to research thoroughly, consult with experts, and choose equipment that aligns with your culinary vision and operational demands. Choosing the right equipment is the first step to culinary excellence, ensuring your kitchen is not just functional, but truly exceptional.